The use of wide bandgap semiconductors in AC drives, which can increase power density, decrease heat dissipation, and improve energy efficiency, could be covered in this topic.

Wide bandgap semiconductors are substances that operate at greater temperatures, voltages, and frequencies because they have a wider bandgap than conventional semiconductors. the following benefits have led to the use of this technology in AC drives:

1. Higher efficiency:

Wide bandgap semiconductors are more efficient and use less energy because they have lower switching losses than conventional silicon-based semiconductors.

In contrast to conventional silicon-based semiconductors, wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) provide a number of advantages in the field of AC drive technology. Higher efficiency is one of the main advantages since these materials have lower switching losses and resistance. As a result, less energy is lost as heat and more energy may be used to power the motor.

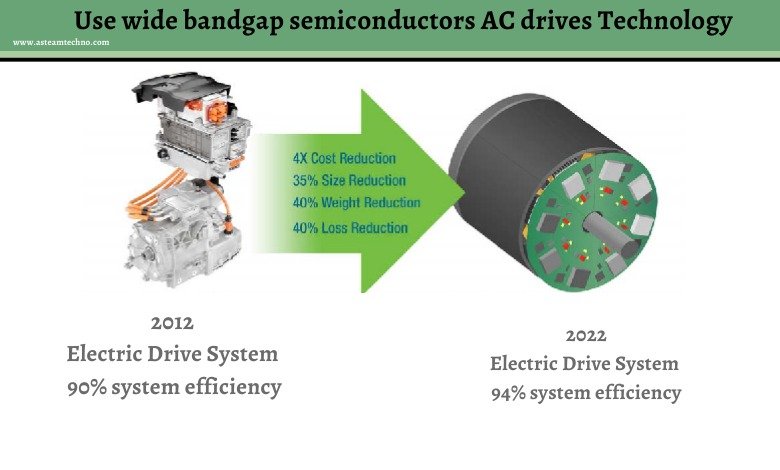

Wide bandgap semiconductors can also operate at temperatures higher than silicon, enabling more streamlined designs and greater power densities. This can result in cost savings since smaller, more effective drives can simplify and simplify the size and complexity of related systems like cooling and power delivery.

Read: Allen Bradley PowerFlex 4M AC drives

Wide bandgap semiconductor-based AC drives are more efficient than conventional silicon-based drives. This is brought on by these semiconductors’ decreased power loss and faster switching rates. The AC drive can convert electrical power more effectively as a result, which lowers running costs and energy consumption. Wide bandgap semiconductors create less heat than conventional silicon-based semiconductors, hence using them minimises the requirement for cooling.

2. Smaller size:

Wide bandgap semiconductors can result in more compact and smaller designs when used in AC drives. These materials can operate at higher temperatures and voltages than conventional silicon-based semiconductors, allowing for the development of more compact and effective power electronics. This makes wide bandgap semiconductor-based AC drives more space-efficient than those that use conventional silicon-based semiconductors and suited for applications where there is a lack of available space. Additionally, smaller AC drives may be less expensive, easier to install, and require less maintenance, all of which could help users save money.

3. Higher power density:

Wide bandgap semiconductors may function at greater voltages and temperatures, which makes it possible to create AC drives with larger power densities.

The power density of wide bandgap semiconductors is also higher than that of conventional silicon-based semiconductors. As a result, AC drives can be made smaller and more compact without compromising power output. AC drives can be used in applications with tight size restrictions or limited space thanks to their superior power density. Additionally, since less installation space and materials are needed, using smaller and more compact AC drives can aid in lowering overall system costs.

In Rockwell Automation 22F-D6P0N103 PowerFlex 4M AC Drive, higher power density refers to the capacity to produce more power in a smaller physical space. The use of more compact and effective components is made possible by developments in semiconductor technology. Equipment designers can create smaller, lighter devices that are easier to transport and install by boosting the power density of AC drives. Higher power densities can also enhance equipment performance overall by enabling quicker response times and improved control precision.

4. Lower cooling requirements:

Wide bandgap semiconductors generate less heat as a result of their lower switching losses, necessitating less cooling and smaller heat sinks.

The lower cooling requirements of broad bandgap semiconductors in AC drives are one of their main advantages. These materials can dissipate heat more effectively because they have a better thermal conductivity than conventional silicon-based semiconductors. Wide bandgap semiconductors allow AC drives to function at higher temperatures without the requirement of additional cooling systems, which reduces the size and complexity of the drive system as a whole. Additionally, since fewer components can malfunction as a result of overheating, lower cooling requirements can also result in cost savings and increased reliability.

Is HPC Computing a Good Role Model for Your Company?

5. Faster switching speeds:

Comparing wide bandgap semiconductors to conventional silicon-based semiconductors, switching speeds can be increased. Wide bandgap semiconductors allow devices to function at higher frequencies, which can result in smaller passive components and more effective power conversion. Faster switching rates can also lead to decreased heat generation and switching losses, which can increase efficiency and decrease the need for cooling. Wide bandgap semiconductors are capable of quicker response times and improved dynamic performance due to their rapid switching rates.

Asteam Techno Solutions Pvt. Ltd. is a commercial and service company specializing in the comprehensive services for our customers, as well as supply of difficult to obtain industrial automation spare parts. The main goal of the company is to limit the customer’s vendors range. Therefore, Asteam Techno Solutions provides everything that their clients need with reduced time of preparing quotations to the absolute minimum. Many years of cooperation with domestic and foreign suppliers has given them the necessary knowledge and experience to be able to offer the highest quality products at competitive prices. We specialize in deliveries of the following brands: Schneider Electrics, Omron, Siemens, Allen Bradley, Phoenix Contact, Moxa, Vipa and many more.